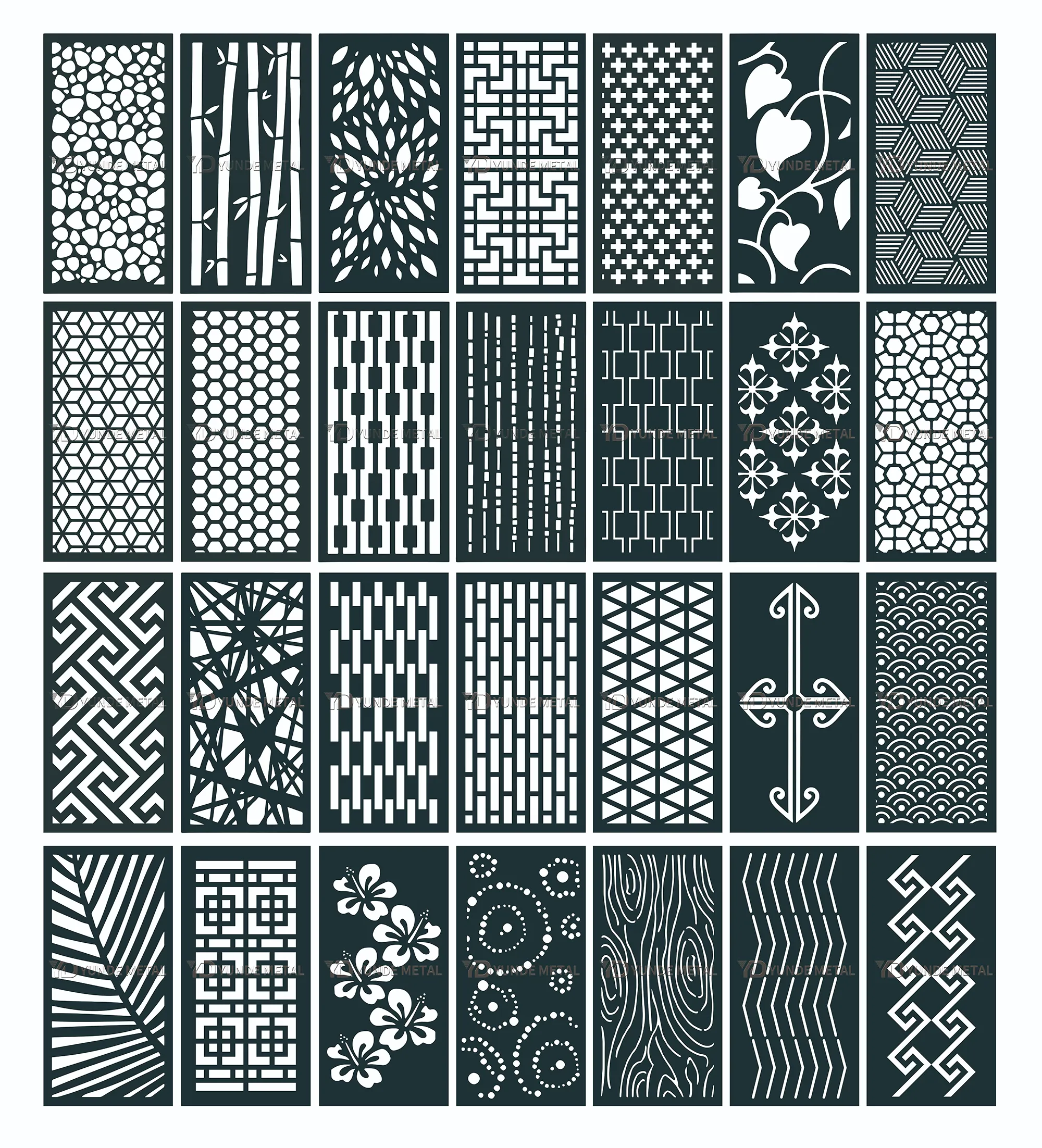

Laser Cut Decorative Mesh

Your Reliable Supplier For Laser Cut Decorative Mesh in China.

What is Laser Cut Decorative Mesh?

Laser Cut Decorative Mesh is a versatile metal material. It's made by precisely cutting patterns into metal sheets using a laser. Common materials include stainless steel, aluminum, or brass. This process creates intricate, uniform, and customizable decorative elements. Widely used in architecture , interior design, and furniture. It combines aesthetics with durability, offering both visual appeal and functional benefits like ventilation and light transmission.

REQUEST A QUOTE CONTACT USYunDe Laser Cut Decorative Mesh Manufacturing Process

YunDe adheres to strict standardized processes to produce high-quality Laser Cut Decorative Meshs, ensuring excellent slip resistance, durability, and consistency.

All raw materials are sourced from premium suppliers. We conduct strict inspections on the appearance, thickness, flatness, and material composition of stainless steel, aluminum alloy, brass, and other metal sheets/coils.

2.Nesting & Programming

Based on customer-provided DXF/DWG drawings or design requirements, we use professional software for optimized nesting and cutting path programming.

3.Precision Laser Cutting

Advanced fiber laser cutting machines are employed for high-precision cutting, ensuring intricate patterns and smooth edges.

4.Post-Processing

A series of fine treatments are applied to the cut products to enhance surface quality and functionality.

5.Quality Inspection & Packaging

Before shipment, we perform a comprehensive final inspection on dimensions, appearance, and performance to ensure products meet customer specifications.

YunDe Available Specifications